Geometry that can’t be machined

The below are some common issues we see when asked to evaluate if a part can be machined or not.

Generally making small changes to address the below points will make a part much more feasible to cut on the Pocket NC.

Sharp inside corners cannot be machined.

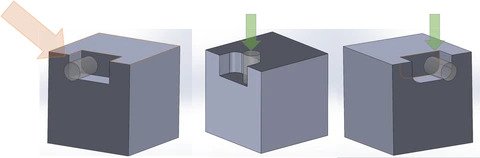

Blind features – do I have a “line of sight” for the tool?

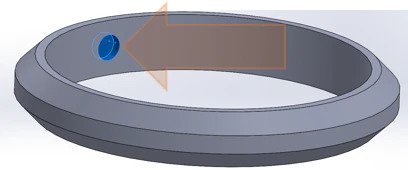

Keep internal radii as big as possible. Aim for depth of at least three times the diameter of tool, machining is exponentially more difficult as this ratio gets larger.