Schunk Zero Point Fixturing on the Pocket Nc V2

The Need

In preparation for running a demo part on a V2 machine at IMTS 2022, we began looking at ways to hold our stock that would accomplish several objectives. Our biggest need was to be able to do all of the machining in our shop in Montana and then “air cut” the finished part on a machine in Chicago without the concern of a crash.

Now, there are a lot of ways we could have gone about this, but all of the more traditional fixturing options require more user input and know-how than we preferred. Since the team members that would be getting to the show first and setting up the demo don’t have as much time with the machine and demo as those that proved it out, we wanted to make it as simple and easy as possible.

It was not long before a few of our team members had the idea of implementing a miniature version of the work holding we use on our big production machines - the Schunk Vero-S modules.

The Solution

Schunk’s Vero-s modules are air actuated vises that clamp and draw down a pin that is mounted to the stock material. Since the clamping pin will be held concentrically to the fixture and draw the base of the stock material right to the face of the fixture, there is only one place for the stock to end up every time it is installed on the fixture. This is what is called a zero point clamping system.

A digital model of Schunk’s Vero-s module and its inner workings.

When paired with an indexing pin (available from Schunk) or boss (machined into the stock), this system allows for accurate, repeatable re-fixturing of stock and pre-machined parts, which is exactly what we needed.

The Implementation

After deciding on the fixture we were going to use, we needed a way to adapt it to the Pocket NC’s B-table. This was quick and easy work for our experienced engineering team. They designed the adapter in Onshape, used Fusion 360 to create the toolpaths and then machined the final part on our Haas UMC 1000, all within a couple of days.

Adapter used to adapt the Schunk module to the B-table.

Next, we needed to do a little stock prep. We chose to pre-machine our stock with a locating boss on it instead of using one of Schunk’s indexing pins. Either of these methods work great, however since the stock needs a small bore and a threaded hole put in it to accept the clamping pin, we decided to just machine the locating boss as well. It is worth noting that even though we used a larger machine, both the adapter and the stock prep could be done on a Pocket NC using the vise that ships with the machine.

Brass stock prepared for mounting to the Schunk module. Note the center bore with threaded hole as well as the indexing boss.

From there we could mount the Schunk Vero-s module to the custom adapter by following the instructions included with the module, attach the clamping pin to the stock and finally mount the stock to the Vero-s module. The Vero-s module requires air to open the clamping mechanism so we had to plumb a fitting into the bottom of the adapter to apply air and open the clamp. We chose to use a push-to-connect swivel connector so that an air hose could stay attached to the adapter through the B-table bore while the machine ran the part.

Adapter, Schunk module and brass stock assembled along with swivel air fitting installed in the bottom.

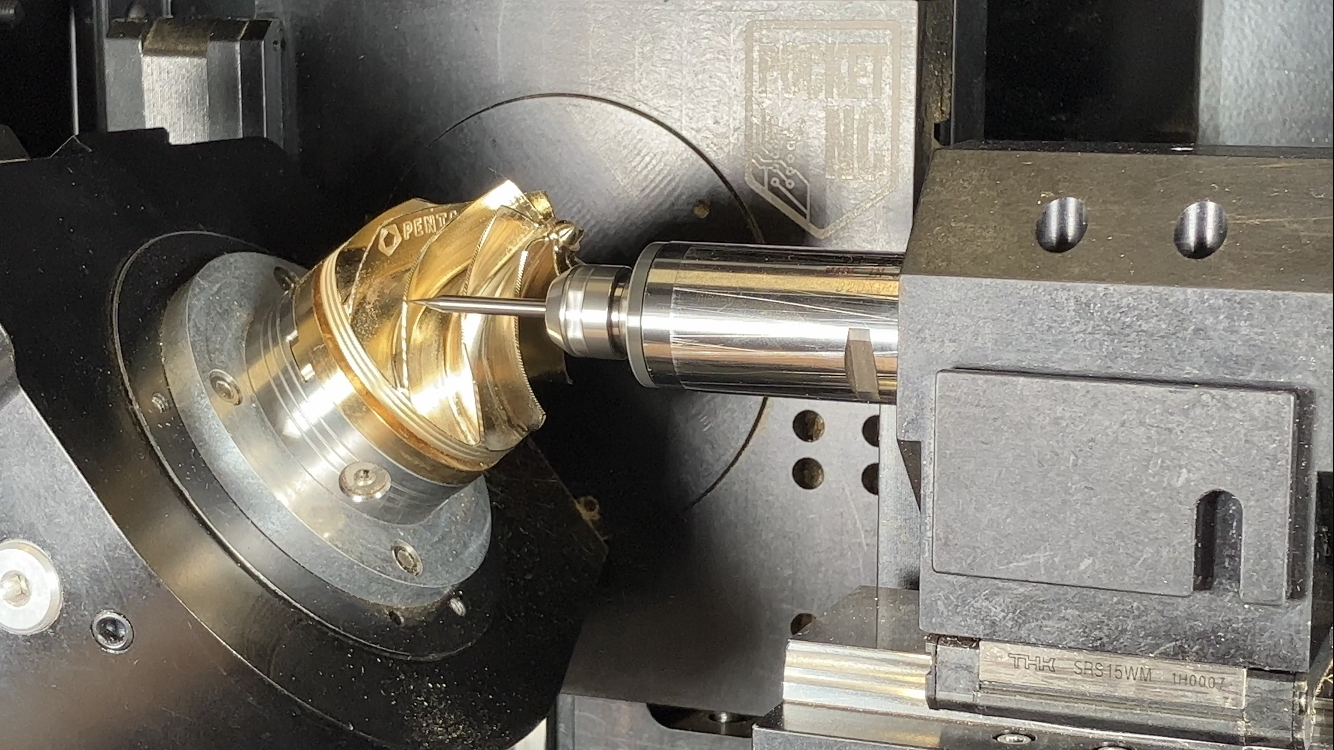

Finally, we could mount the whole assembly onto the V2 machine and begin to machine the demo part we planned to run at IMTS - a brass impeller.

Schunk zero point fixture being used on the V2-50 CHK.

This fixturing option performed excellently for the needs we expected as well as several that we did not expect. For example, after finishing several of the impellers we decided to add another engraving to them, which meant we were going to have to remount them to the machine and attempt to engrave on finished parts. With this system we were able to take all three previously machined parts, put them back on the machine, and perfectly engrave on another blade without any issue or having to adjust work offsets. And, of course, the system allowed for easy, reliable set up at the show.

In summary, Schunk’s zero point fixturing option, the Vero-s module, is a great way to achieve accurate, repeatable fixturing that allows easy part change-out while maintaining a strong hold on the stock material. This is especially useful in situations like (but not limited to) the following:

A part needs to be removed from the machine for test fitment but may still need some additional machining afterwards.

Parts have an initial operation done on one machine (maybe also using a Vero-s module) and then get a second operation done on another.

A variety of fixture types are used on a single machine and a user needs a way to accurately and quickly swap them out.

A batch of parts needs to be run by an operator that is not familiar with the machine and/or setting the work offsets necessary for the part.

Do it yourself

While exhibiting this fixture setup at IMTS, we learned there are a lot of Pocket NC users that would like to implement this setup on their own machines. To aid in that, we have put together a list of the items we used, along with links and other useful information for sourcing those items.

| Item | Qty | Source | Notes |

|---|---|---|---|

| Schunk Vero-S NSE mikro 49-13-V10 Module | 1 | Schunk Retailer | Penta Machine Co. is a Schunk retailer. Please reach out for a quote. |

| Schunk SPA mikro 10 clamping pin | 1 | Schunk Retailer | Penta Machine Co. is a Schunk retailer. Please reach out for a quote. |

| M3 x 14 SHC Screw | 1 | McMaster Carr or local hardware store |

This will not match the threads in the Schunk clamping pin. It is meant to pass through the clamping pin and thread into the stock. |

| B-table adapter | 1 | Local machine shop or cut on Pocket NC machine |

The model for the adapter can be downloaded from Penta’s User Resources website. |

| M4 x 10 SHC screw | 4 | McMaster Carr or local hardware store |

Used to fasten adapter to B-table. |

| ⅛” diameter x ½” long dowel pin | 4 | McMaster Carr or local hardware store |

Used to locate adapter on B-table. |

| M3 x 4 flat set screw | 1 | McMaster Carr or local hardware store |

Installed in the side of the adapter's bottom boss to seal air passage. |

| Rotating push-to-connect air fitting | 1 | McMaster Carr or similar supplier |

Other versions of this part could be used in the case that a different air hose is being used. |

| *Optional* Air directional control valve | 1 | McMaster Carr or similar supplier |

Used to quickly and easily open and close the Vero-s module. |

| *Optional* ⅛” NPT to push-to-connect adapter | 2 | McMaster Carr or similar supplier |

Used to adapt control valve to push-to- connect fittings that match rotating fitting. |

Please feel free to reach out to us at info@pentamachine.com with any questions about this setup or any of its components, we are happy to do what we can to help!